Choosing an OEM Dietary Supplement Manufacturer: A Comprehensive Guide

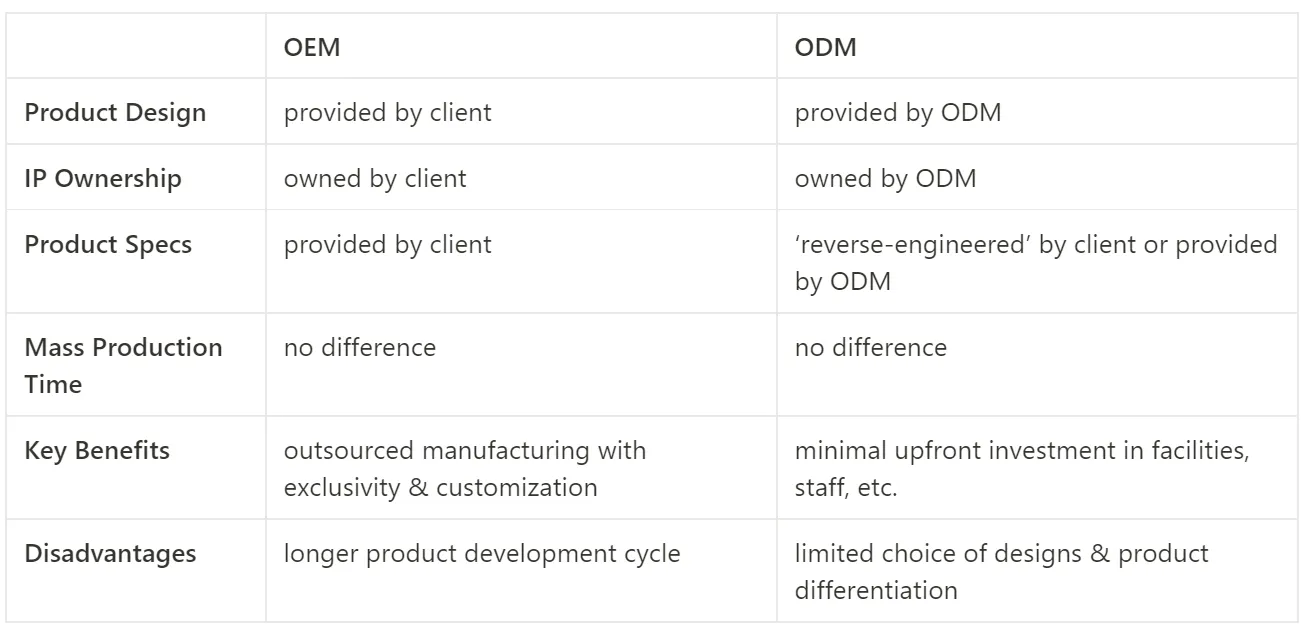

Designing, producing, and marketing nutraceutical products can be daunting, particularly due to high factory setup costs. A viable solution is leveraging Original Equipment Manufacturer (OEM) services. OEMs allow businesses to outsource production while maintaining control over their product designs, ideal for those focusing on branding and marketing. Additionally, there are Original Design Manufacturers (ODMs) who not only manufacture but also create shelf-ready products, which businesses can then brand as their own. The choice between OEM and ODM hinges on the desired level of control and customization over the products. This introduction presents both options, outlining their roles in aiding companies in the dietary supplement industry.

Learning what OEM & ODM respectively mean and how to leverage each option is an important step in starting or running your food and dietary supplement business. Read on to uncover the essentials of OEM vs ODM, their features, pros and cons, and which one will best suit your business needs.

Understanding OEM & ODM

Defining OEM and ODM

OEM involves outsourcing a product's manufacturing to a third party that builds it as per the client's specifications and branding. ODM, however, entails a partnership where the manufacturer produces and provides the product's formulation, design, and sometimes branding, limiting the client's customization options.

In the context of a dietary supplement business, an OEM partnership would mean supplying your unique formula and label design to a manufacturer, ensuring control over the product's identity. On the other hand, an ODM partnership would involve using a pre-existing formula and label design from the manufacturer, offering less customization for your brand.

Differentiating between private and white-label methods is crucial. Private label involves buying and rebranding pre-made products. In contrast, white label offers varying degrees of customization, with some manufacturers allowing complete label changes, while others limit alterations to preserve the product's or brand's original image. OEM and ODM, however, provide more customization and control than these options.

The Role of OEM in Dietary Supplements

In this industry, OEM manufacturing means collaborating with a manufacturer who produces supplements exclusively for your brand, using your specific formula, ingredient standards, and label design. This ensures the end product aligns with your brand's identity and quality standards.

Apple’s collaboration with Foxconn to produce iPhones is a typical example of the OEM model. Apple invented and designed iPhones but despite its superior R&D capacity, Apple lacks a manufacturing component. This is why iPhones are contract manufactured by the Taiwanese company Foxconn, while Apple retains its original design.

OEMs hold a key position in product development. They are essential for companies that have the expertise to create and market a product. However, these companies often lack the capacity for large-scale manufacturing. This is where OEMs step in, bridging the gap in production capabilities.

Imagine a beginner kombucha brewer who developed a unique, excellent-tasting formula. This formula gained immense popularity in her neighborhood, sparking her interest in starting a business. However, she faces challenges due to a lack of production facilities and experience in commercial-scale batch brewing. In such a scenario, a kombucha OEM service provider can offer the necessary support and expertise.

Advantages of OEM Partnerships

Partnering with an OEM offers numerous benefits:

-

Quality Assurance: Control over ingredients and processes ensures products meet your standards.

-

Labeling and Certification: Beyond ensuring regulatory compliance, this step boosts consumer trust and adds product value, key factors in market differentiation and customer decision-making.

-

Custom Packaging: Creates packaging that not only stands out but also tells your brand's story, drawing in customers.

-

Manufacturing Specialization: Guarantees top-quality products that keep your customers coming back for more.

-

Expertise in Ingredients and Formulation: Offers cutting-edge know-how, ensuring your products cater to what your market wants and needs.

-

Minimum Order Requirements: Negotiable order quantities for efficient inventory management.

-

Fulfillment and Logistics: Ensures your products are always available and delivered on time, keeping your customers happy and well-supplied.

-

Manufacturing Transparency: Builds a strong partnership through open and honest communication, making collaboration smooth and effective.

-

Customer Support: Offers dedicated support, quickly resolving any concerns, ensuring a seamless experience for your customers.

-

Lead Time and Scalability: Adapts production to your business needs, ensuring you can meet customer demand efficiently as your business grows.

The Role of ODM in Dietary Supplements

ODM manufacturing means the producer manufactures the product and offers design and formulation services. Clients can select from pre-existing designs and formulations, reducing the scope for customization but enabling quicker market entry.

Have you ever noticed how fast fashion apparel often carries similar-looking designs? It’s a classic (and environmentally controversial) example of ODM manufacturing. This approach enables fast fashion brands to quickly produce and distribute trendy, similar-looking designs, capitalizing on current fashion trends with speed and efficiency.

Referring back to our previous kombucha example. This time, the case in point is an established beverage brand that is about to launch a new kombucha product line. It’s open to various formulas and would like to find the sweet spot between mass market and premium. Consulting a kombucha ODM service provider would be a great option.

Advantages of ODM Partnerships

Working with an ODM provides:

-

Speed to Market: Faster product launches due to pre-designed formulations.

-

Reduced R&D Costs: Lower investment in research and development.

-

Design and Formulation Expertise: Access to established designs and formulations.

-

Market Trends Insights: Benefit from the manufacturer's understanding of current market trends.

-

Regulatory Compliance: Ensures products meet industry standards.

-

Brand Differentiation: Opportunities for brand differentiation through slight customizations.

-

Economies of Scale: Potential for cost savings due to the manufacturer's scale of operations.

-

Risk Management: Reduced risk in product development and launch.

-

Global Reach: Access to global markets through the manufacturer's distribution networks.

-

Innovation and Continuous Improvement: Leverages the ODM's ongoing product innovation.

Top 10 Considerations for Choosing an OEM Manufacturer

1. Quality Assurance

Choose an OEM or ODM manufacturer committed to high quality, adhering to Good Manufacturing Practices (GMP), and performing thorough quality checks. This ensures that both original and adapted designs become market-ready products.

2. Labeling and Certification

Choose an OEM or ODM manufacturer committed to high quality, adhering to Good Manufacturing Practices (GMP), and performing thorough quality checks. This ensures that both original and adapted designs become market-ready products.

Choose a manufacturer skilled in accurate product labeling and compliance with regulatory standards. Accurate labeling and certification are essential steps in the OEM/ODM process, from ingredient sourcing to final product compliance.

3. Custom Packaging

Opt for a manufacturer capable of providing custom packaging that enhances your brand's appeal. Custom packaging, a part of comprehensive OEM/ODM solutions like those offered by companies such as Champion-bio, is crucial for brand differentiation and market appeal.

4. Manufacturing Specialization

Select an OEM or ODM with dietary supplement expertise, essential for delivering high-quality products. This expertise is crucial in the nutraceutical industry for both standard and customized product types, impacting the final product quality.

5. Expertise in Ingredients and Formulation

Partner with a manufacturer having deep knowledge in ingredients and formulation, essential for creating effective consumer products. This expertise is crucial for OEM/ODM services to ensure the product meets market demands and consumer expectations.

6. Minimum Order Requirements

Ensure the manufacturer's minimum order requirements suit your production and financial needs. This flexibility is vital in OEM/ODM services, accommodating various business sizes and allowing for efficient scaling.

7. Fulfillment and Logistics

Evaluate their capabilities in storage, order fulfillment, and logistics. Efficient distribution systems are vital for quickly tapping into market opportunities with minimal upfront investment.

8. Manufacturing Transparency

Good communication and transparency are crucial. Choose a manufacturer that values open communication, enhancing collaboration in the OEM/ODM process. This transparency aids in maintaining a clear understanding of the manufacturing process and product development.

9. Customer Support

Assess the manufacturer's customer support level. Effective communication is key in resolving issues quickly, a fundamental aspect of successful OEM/ODM partnerships, ensuring a smooth process from concept to market.

10. Lead Time and Scalability

Understand their production lead times and scalability. Timely delivery and the ability to meet market demands are essential in OEM/ODM for quick market entry, especially in competitive industries like nutraceuticals.

OEM or ODM, Which Is Right for Your Business?

Working with an outsourced manufacturer saves the need for a large amount of initial investment. It also helps ease the burden when it comes to operational staff requirements, production scheduling, facilities, and space constraints. Once such operational complexity is offloaded to an external partner, companies will be able to concentrate resources on what truly distinguishes them from other competitors.

Working with an outsourced manufacturer saves the need for a large amount of initial investment. It also helps ease the burden when it comes to operational staff requirements, production scheduling, facilities, and space constraints. Once such operational complexity is offloaded to an external partner, companies will be able to concentrate resources on what truly distinguishes them from other competitors.

Whether a client should choose an OEM or ODM service depends on their circumstances and business goals. By taking the OEM path, you come up with big ideas, get ready to capture market attention in your own unique ways, and co-create the final products with a manufacturing expert. If choosing the ODM approach, you get inspired by pre-made designs that can be customized to some degree, trusting an experienced manufacturer in your niche with the majority of your production outputs.

Champion: Your OEM Dietary Supplement Manufacturer

Understanding the differences between OEM and ODM services and the key considerations discussed in this article will empower you to make an informed decision. Champion's comprehensive services and commitment to excellence make us a top choice for your OEM dietary supplement manufacturing needs.

By working closely with verified ingredient suppliers, testing labs, quality control and assurance, and all points along the international supply chain, Champion takes pride in offering a wide range of OEM/ODM services to co-create nutraceutical products that stand out on the shelf with our clients:

-

Private/White-Label Supplement Manufacturing

-

Nutraceuticals Product Development

-

Custom Formulas & Formulation Design

Contact Us Today for more information.